Services

Production from sketch design to finished product.

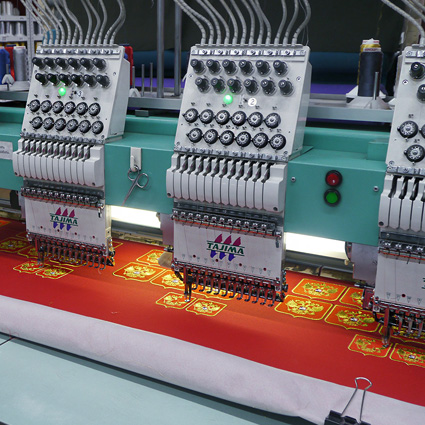

The total production area of the enterprise is more than 15,000 m². The production of sewing products of the widest range and complexity, including products with seam sealing and threadless technologies, is possible due to the availability and regular updating of both universal and specialized equipment from the world's leading manufacturers: “Juki”, “Brother”, “Pfaff”, “Stirovap”, “Kannegisser”, ‘Rotondi”.